Metal injection moulding (MIM) combines powder metallurgy with plastic injection moulding and metal die-casting technology. It is generally used to produce products with small size and complex shape. Powder metallurgy and metal injection moulding complement each other and are used according to the characteristics of products.

What are the differences and relations between powder metallurgy and metal injection moulding?

Powder metallurgy needs injection moulding technology:

The process of powder production includes the steps of powder preparation and powder mixing. In order to improve the formability and plasticity of powders, plasticizers such as oil, rubber or paraffin are usually added. The injection-moulded powder is pressed into the desired shape under 15-600 MPa pressure. There are many kinds of pressing process, which are widely used in practical industrial applications. Cold closed steel die pressing, cold isostatic pressing, hot isostatic pressing and warm pressing all belong to pressing forming. Press forming, dry powder is filled in the die by gravity, and extruded by external pressure. In injection moulding, a very fine powder and a large amount of thermoplastic binder are injected into the moulding die. In addition, there are two special processing methods of powder metallurgy parts: powder forging and powder rolling.

2. Metal injection moulding is a new method of powder metallurgy.

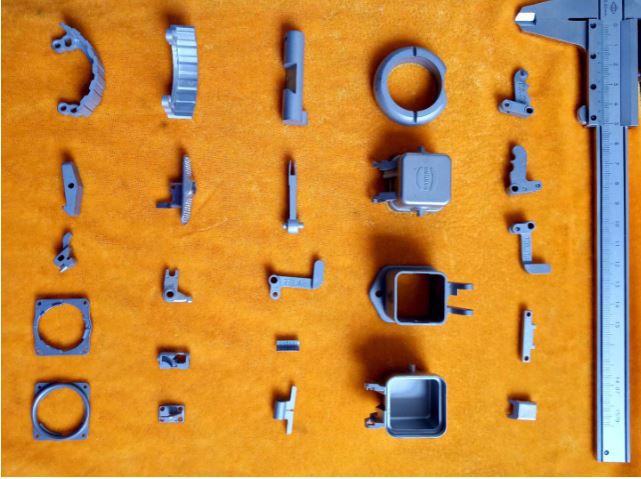

Metal injection Molding (MIM) is a new near net-shape powder metallurgy (PM) technology developed from the plastic injection molding industry. Injection moulding technology can produce various complex shaped products at low prices, but the strength of plastic products is not high. In order to improve the performance, metal or ceramic powder are added to plastic to obtain products with high strength and good wear resistance. In recent years, this idea has evolved to maximize the content of solid particles and completely remove the binder after sintering so as to densify the forming blank. This new powder metallurgy forming method is called metal injection molding.

Metal injection moulding (MIM) combines powder metallurgy with plastic injection moulding and metal die-casting technology. It is generally used to produce products with small size and complex shape. Powder metallurgy and metal injection moulding complement each other and are used according to the characteristics of products.