MIM technology has been proved to be a feasible method to produce complex and complex shape metal parts for various applications, such as endoscopic and laparoscopic instruments, orthodontic and surgical tools, and implants. They are made of stainless steel, cobalt and titanium alloys, and ceramics.

In terms of global manufacturing, the current technology needs are being reviewed in terms of cost and added value. Every medical device manufacturer is looking for the possibility of establishing a more streamlined supply chain without sacrificing the quality demand.

In recent years, biocompatible materials have indeed begun to affect the development of medical devices, and expand the potential for developers and manufacturers as well as for the treatment methods provided for patients. However, they pose challenges to manufacturers because of their potentially complex contours and shapes. Metal injection molding (MIM) is a manufacturing process that has helped many global medical device manufacturers to meet these challenges.

MIM technology enables medical device manufacturers to design unique products without the cost limitation of traditional metal forming technology. The freedom provided by MIM impressed medical device manufacturers. It meets their needs, enabling them to focus on identifying next-generation technologies that can help deliver cost-effective solutions while maintaining the same quality and safety requirements. MIM technology combines the design flexibility of plastic injection molding with the strength and integrity of forged metal.

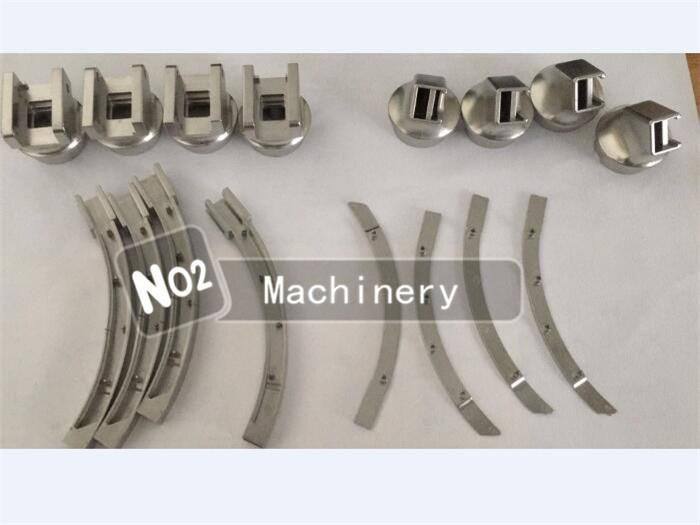

MIM technology has been proved to be a feasible method to produce complex and complex shape metal parts for various applications, such as endoscopic and laparoscopic instruments, orthodontic and surgical tools, and implants. They are made of stainless steel, cobalt and titanium alloys, and ceramics.

The survey also concluded that the MIM process is sustainable because it produces relatively less carbon dioxide and consumes less water. For more information about our MIM process, please contact us.

| Shandong No2 Machinery Company |

| ADD:No.1,Huan Road,Hutian,Zibo,Shangong,Province,China | |

| Phone:+86-136-6262-4231 | |

| E-mail:sales@no2machinery.com | |

| Skype:bretchen1128 |