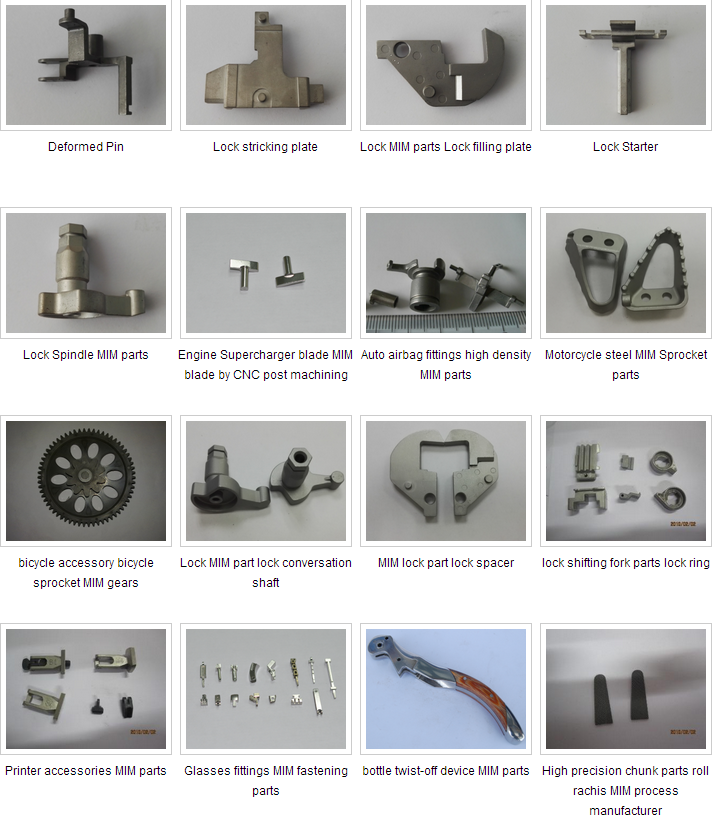

Technology: PIM(Powder Injection Moulding)

Description: Lock Bolt, Lock Parts, Steel Lock Parts

Material:SUS316L

Requirement: Need 2D and 3D drawings, customed

Supply Ability: 50000 pcs per month

Lead Time: 25-35 Days

Technology: PIM(Powder Injection Moulding)

Description: Lock Bolt, Lock Parts, Steel Lock Parts

Material:SUS316L

Requirement: Need 2D and 3D drawings, customed

Supply Ability: 50000 pcs per month

Lead Time: 25-35 Days

Package: Standard Carton or Neutral Package

Shipment: DHL, Fedex, UPS Or Air freight

Company Introduction:

NO.2 Machinery is a leading developer and manufacturer of MIM products in the field of metal injection moulding technology and Military Industry. No2 Machinery's original factory was built at year 1965. We have MIM(metal injection molding) military factory started at year 2004.

We have 350 employees, including 80 technicians, 60 senior engineers. Our factory covers an area of 108,000 square meters. The registed capital is 10millions RMB, total capital 100millions.We have more than 1200sets of Injection machines, sintering furnaces, degreasing machines,CNC lathes, Multi-purpose Tool Machines and testing equipments. With constantly enhancing and improving factory management, we have obtained various quality certificates including GBT/T 19001-2008/ISO 9001:2008, China Arms Assembling Certificate, Grade II Physical and Chemical Detection of Weapon Industry, Grade III National Defence Metrology Organization etc.

Here we want to introduce how to remove and install lock cylinder.

Remove the lock core sequence:

1. Remove the inner and outer handle panels: the screw is on the inside handle panels, the top one and the bottom one.

2. Remove the inner and outer lock cap: The screw is on the inner lock cap, which is the left and right sides of the key.

3. Remove the lock core positioning screw: the screw is on the side of the door, in the middle of the lock tongue, at the same height as the lock core. The thickest one is the one.

4. At this time, the old lock core can be removed: the old and new lock core can be replaced just like the new one.

Install new lock core:

The order is contrary to that of disassembly. We should pay attention to several points:

1. Before installing a new lock core, add a small amount of special lubricant for the new lock core. Turn the key several times.

2. Lock core positioning screw must be tightened to prevent the screw from loosening and not opening the door properly.

3. Don't tighten the core cap screw to prevent screwing and unlocking.

4. When installing the inner handle panel, there is a safety bolt below, which should be inserted into the corresponding safety bolt hole.