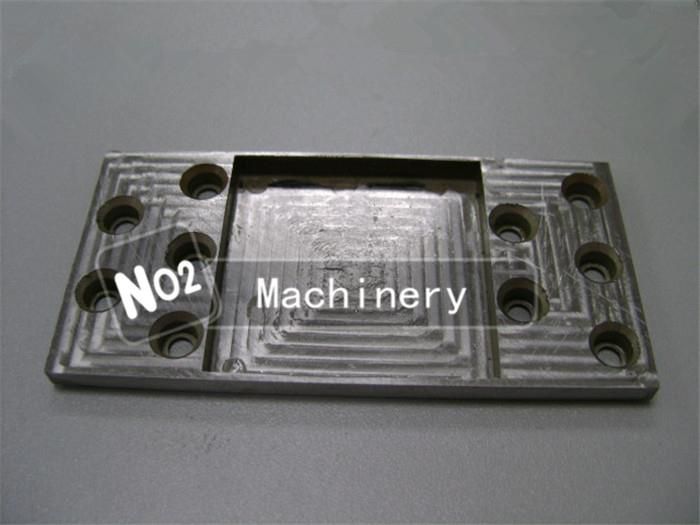

Process:MIM(Metal Injection Moulding)+CNC machining

Material: AISI316L

Demension:28.6mm*42.8mm*4.0mm

Hole: Drilling

Surface Finish: Ra0.8

Difficulties: Surface Evenness

Process:MIM(Metal Injection Moulding)+CNC machining

Material: AISI316L

Demension:28.6mm*42.8mm*4.0mm

Hole: Drilling

Surface Finish: Ra0.8

Difficulties: Surface Evenness

Stainless steel-316 is one of the most welcome material in MIM technology. It has better air and industry corrosion resistance than 304. Discontinuity-use below temperature 871C(1600F) and continuity-use above 927C(1700), it has wonderful oxidative resistance. It is widely used in switches for paper making, shells, gun parts, lock parts etc..

Stainless steel-316L contains less carbon than 316. Compared with 316, it has better mechanical properties and performance. The material cost is higher than 316 as well.

MIM | Powder metallurgy | Die casting | CNC machining | Pressing | |

Product density | 96% | 86% | 96% | 100% | 100% |

Product tensile strength | High | Low | High | High | High |

Product surface finish | High | Medium | Medium | High | High |

Product miniaturization ability | High | Medium | Low | Medium | High |

Product thickness | High | Medium | Medium | Low | High |

Product complexity | High | Low | Medium | High | Low |

Product tolerance | High | Medium | Medium | Medium | Low |

Material application rang | High | High | Medium-High | High | Medium |

Mass production ability | High | High | Medium | Medium-High | High |

As a new machining technology, MIM’s development is influenced by several facts which decide the prospect, speed and trend of this technology. If these facts can be well researched, MIM will make a great step. Otherwise, it will be blocked.

MIM material includes metal powder and binders. Simply, we mix the two materials according to a proper rate, in a proper order, under high temperature and shear forces, so as to get a well-distributed structure combined material, then, pelleted by the granulator. Because of the binders, the material after pelleted have good fluidity, and can be fully filled into the molds. After forming, degreasing the binders from the blanks and sinter them, so to have the final products.

Since 1970s, after 40years development, MIM achieved a great progress. Also, some defects and weak-points expose out which block MIM’s further step.