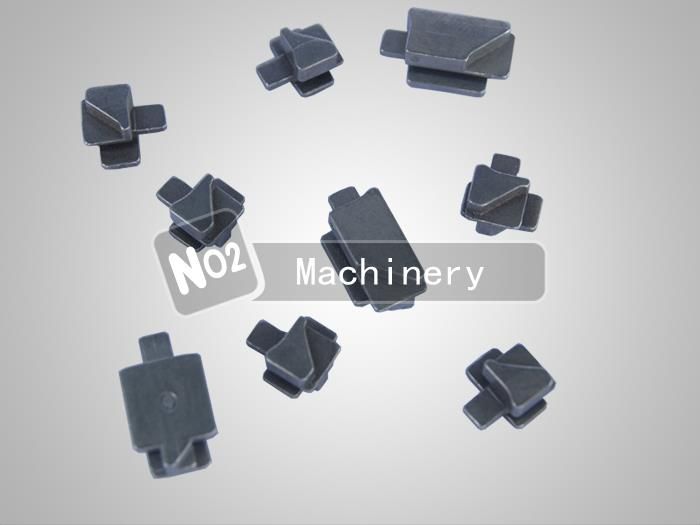

Material: SUS440C

Density: ≥ 7.5g/cm3

Hardness: 220-250HV10

Tensile strength: ≥600mpa

Yield strength: ≥350mpa

Elongation: ≥8%

Feature:Many hand tool parts are made of SUS440C, which is less popular than 316L and 304. 440C stainless steel is a martensitic stainless steel with high carbon and chromium content. The carbon content is 1.0% and the chromium content is 17%.

Scissors are common livelihood hardware. High hardness scissors are generally made by stainless steel forging. As is known to all, the traditional way to make scissors is forging. It is labor intensive industry which takes time and trouble.

Nowadays, hand tools can be made by MIM technology instead of traditional forging. Especially for high hardness stainless steel MIM blade clamp, MIM can make them one shot, and have good density, wonderful mechanical performance.

According to different metallographic structure, stainless steel can be divided to austenitic, martensitic stainless steel etc., or can be called magnetic and non magnetic stainless steel. To make high hardness scissors, the common materials are SUS420 and SUS440 martensitic stainless steel, because its hardness is higher than 58HRC, and have good abrasion resistance as well as resistance to corrosion which can satisfy people’s demands for blade clamp.

To make hand tools spare parts by MIM, the first step is to make stainless steel feed material, putting SUS440C powder and the water soluble binder into mixing mill and granulating machine to make out the feeding material.

Secondly, pour the feeding material into the injection machine to make out the blanks. Then, two steps to degrease the binder, 1, shrend the PEG components from the blanks. 2, warm the blanks and resolve PMMA.

After degreasing, immediately put them into sintering furnace and increase furnace temperature for sintering. Keeping this process for 40minutes, then, the blanks will cold down to room temperature. Afterwards, heat treatment them. Finally, the complete stainless steel scissors are finished.

Throughout the whole process, the most important step is stainless steel feeding, because the following sintering and products final performance will be influenced by stainless steel powder and binder. So we must think highly of this process when making scissors by MIM technology.

Scope of application: Mainly used for manufacturing bearing parts working in corrosive environment and non-lubricating strong oxidation atmosphere. 440C has good dimensional stability at high temperature, so it can also be used to make corrosion resistant high temperature bearing steel. In addition, it can also be used to manufacture high quality cutters, such as medical scalpels, scissors, nozzles, bearings, etc. 440C has low dynamic load capacity.

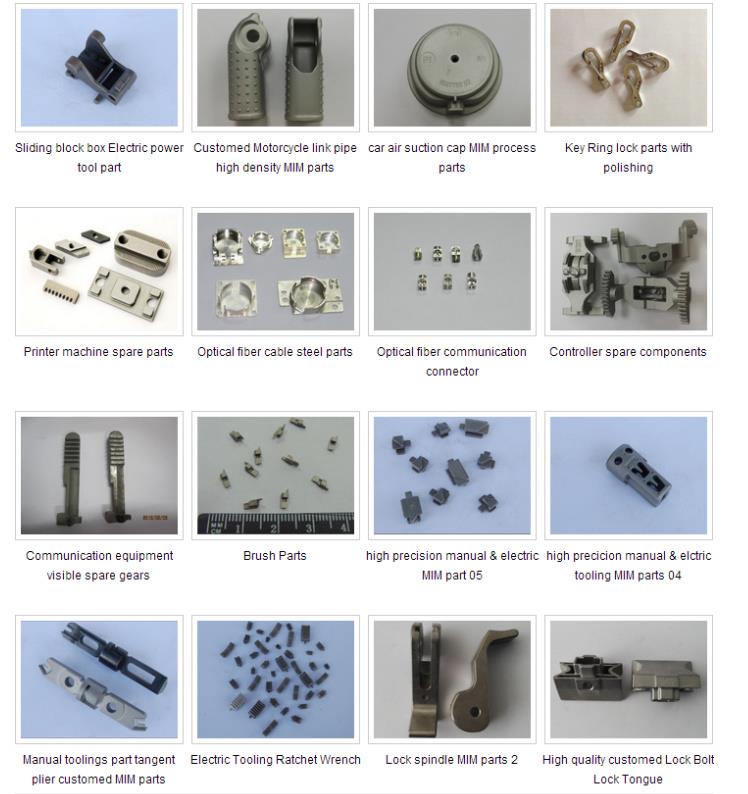

MIM technology can make various kinds of metal parts. If your part is made of stainless steel, steel, iron and the shape is complex, MIM is the best choice. If you want to make metal components by MIM, you need to send us the parts drawings, including PDF and 3D files in which, we can see the shape, sizes, tolerance and other requirements such as surface treatment, hardness(HRC). Also, we need to know the quantity for the part. Because to make MIM items, the mold is important. To make a mold is around 3000--5500USD that based on the shape, so if the customer have several parts to produce, we suggest to put them in one mold to save cost.