When making MIM tools, the general alternating is 20--50 Mpa with cool and hot change. When making super precision MIM tools, the molding press is several times than normal ones. MIM tools file can be hundreds of thousands times, so it must be tough and hard enough.

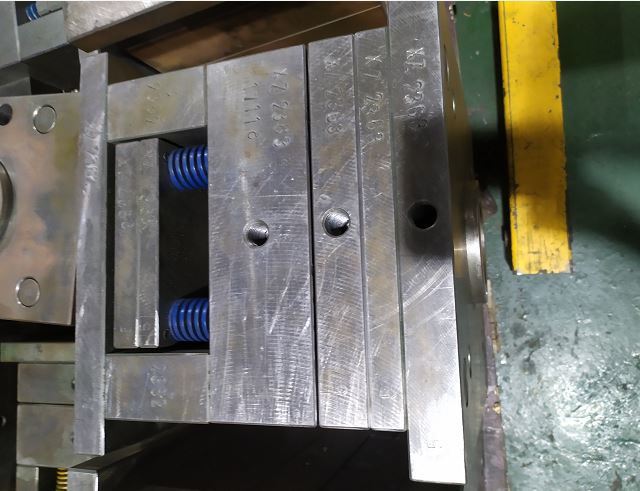

MIM tools can be simply divided into mold base and chamber.

Metal injection mold bases are the same as plastic injection ones. The material of movable platen and thrust plate is usually #45 steel, thermal refining hardness is 189--250HBS. Other plate material can be #45 steel or Q235 steel. For those high requirements mold cases, all plate material can use #45 steel, or even the micro-deformation tooling steel like Cr12 to anneal. The guide pins and guide bushings can use T8A annealing to 50--55HRC or #20 steel carburizing thickness to 0.5--0.8mm and annealing to 56--60HRC.

When making MIM tools, the general alternating is 20--50 Mpa with cool and hot change. When making super precision MIM tools, the molding press is several times than normal ones. MIM tools file can be hundreds of thousands times, so it must be tough and hard enough.

The hardness of MIM tools mold chamber is usually 58--62HRC, so need to pay much attention on the sharp edges, grooves, cut and the stress concentration caused by the defects during machining. These defects will largely reduce the fatique strength.