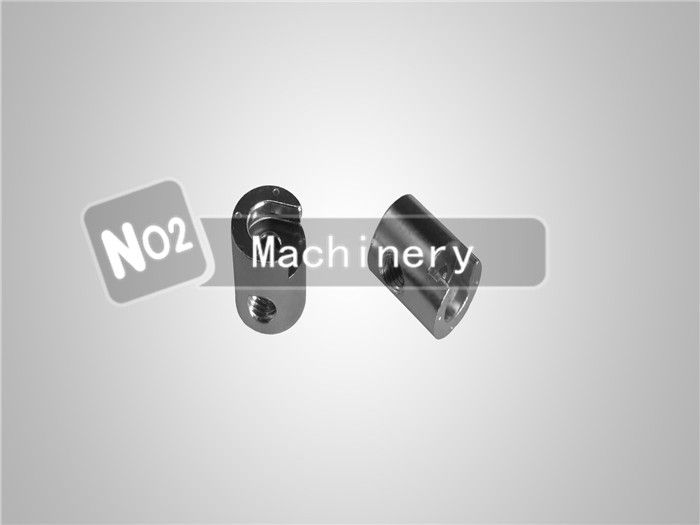

Material: SUS316L

Density: ≥ 7.8g/cm3

Hardness: ≥ 120 HV10

Tensile strength: ≥500mpa

Yield strength: ≥180mpa

Elongation: ≥50%

Feature:The steps of MIM are as follows: firstly, metal powders and binders that meet MIM requirements are selected, and then powder and binder are mixed into uniform feeds at a certain temperature by appropriate methods. After pelletizing, the formed blanks are injected and formed. After degreasing, sintering and densification, the formed blanks are finally formed. Product.

MIM Powder and Pulverizing Technology

MIM has high requirements for raw material powder, and the choice of powder should be conducive to mixing, injection moulding, degreasing and sintering, which are often contradictory. The research on MIM raw material powder includes powder shape, particle size and size composition, specific surface, etc. The properties of raw material powder most suitable for MIM are listed in Table 1.

Because of the high requirement, the price of MIM raw powder is higher, and some of them even reach 10 times of the price of traditional powder metallurgy powder. This is a key factor restricting the wide application of MIM technology. At present, the main methods of producing MIM raw powder are carbonyl method, ultra-high pressure water atomization method, high pressure gas atomization method and so on..

MIM technology can make various kinds of metal parts. If your part is made of stainless steel, steel, iron and the shape is complex, MIM is the best choice. If you want to make metal components by MIM, you need to send us the parts drawings, including PDF and 3D files in which, we can see the shape, sizes, tolerance and other requirements such as surface treatment, hardness(HRC). Also, we need to know the quantity for the part. Because to make MIM items, the mold is important. To make a mold is around 3000--5500USD that based on the shape, so if the customer have several parts to produce, we suggest to put them in one mold to save cost.