Metal powder injection molding (MIM) USES chemical or thermal decomposition method to remove the binder in the forming billet and obtain the product through sintering densification. Compared with the traditional process, MIM technology has the characteristics of high precision, uniform organization, excellent performance, low production cost, and so on. So what is the process of metal powder injection molding to make MIM mobile phone accessories? Next, dahong new material small series to introduce its process.

Metal powder injection molding (MIM) USES chemical or thermal decomposition method to remove the binder in the forming billet and obtain the product through sintering densification. Compared with the traditional process, MIM technology has the characteristics of high precision, uniform organization, excellent performance, low production cost, and so on. So what is the process of metal powder injection molding to make MIM mobile phone accessories? Next, dahong new material small series to introduce its process:

1. Glue mixing: metal powder and binder are mixed in a certain proportion to form uniform feeding. The binder used in MIM technology has the function of enhancing powder fluidity and maintaining blank shape.

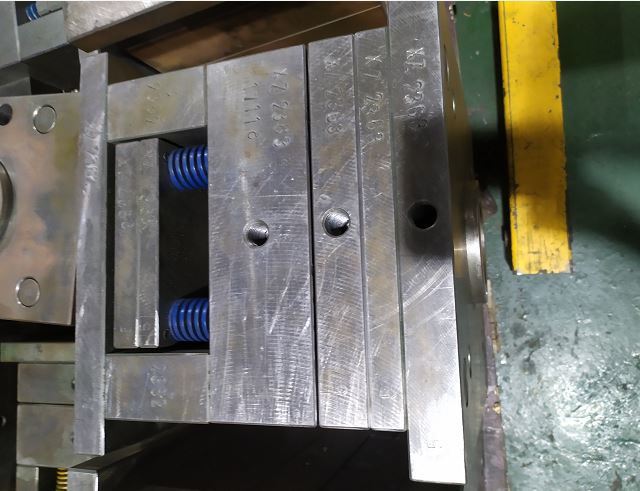

2. Injection molding: high temperature, high pressure and high speed injection molding are used to inject the feeding material into the mold, and the feeding material flows into the mold cavity through the nozzle (the number of mold cavities is designed according to the structural characteristics of the product to improve the production efficiency). After compaction and cooling, the injection blank is formed. The blank has certain strength and density. In dahong new material, the design of die cavity should take into account the shrinkage ratio of sintered blank, which varies according to the material composition.

3. Degreasing: after degreasing, 98% of the binder of the blank body will be removed, leaving 2% to maintain the blank form. When degreasing comes out of the oven, the metal powder injection molding manufacturer will take samples for destructive testing. If the powder is soft when the body is chopped, then it is qualified for degreasing; if it is hard, then it is not qualified for degreasing.

4. Sintering: after 24 hours of sintering, the remaining 2% binder is completely removed. After sintering, the product has high density and good mechanical and physical properties. Sintering processing is the process of metal injection molding MIM manufacturing mobile phone accessories.

Now with the development of economy, the market needs to produce lighter, thinner and more beautiful mobile phone, need to use advanced metal powder injection molding technology, in order to reduce the size and weight of mobile phone accessories, metal powder injection molding MIM is suitable for manufacturing MIM mobile phone accessories.

| Shandong No2 Machinery Company |

| ADD:No.1,Huan Road,Hutian,Zibo,Shangong,Province,China | |

| Phone:+86-533-2070506 | |

| E-mail:sales@no2machinery.com | |

| Skype:bretchen1128 |