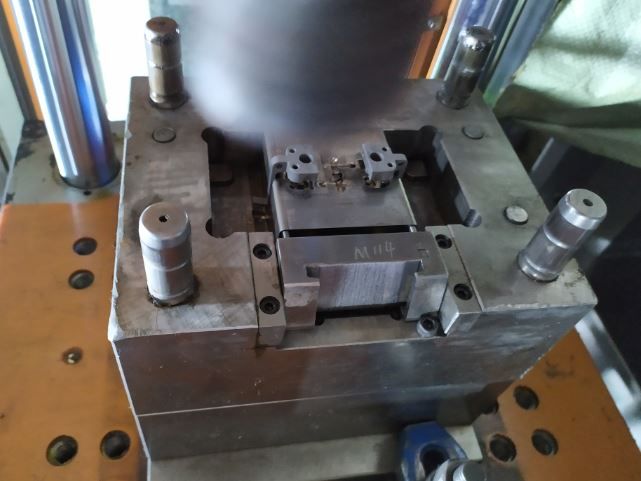

Tooling Core Material: SKD11 Die Formwork Material:SKD11 Cavity:1+1 Glue Gate Way:Big Water Inlet Pattern Method: PL Product Shrinkage: 1.216 Core Hardness:52-58HRC Mould Design Requirement: There are several differences between MIM and standard plastic molds. MIM thermal conductivity of the...

Tooling Core Material: SKD11

Die Formwork Material:SKD11

Cavity:1+1

Glue Gate Way:Big Water Inlet

Pattern Method: PL

Product Shrinkage: 1.216

Core Hardness:52-58HRC

Mould Design Requirement:

There are several differences between MIM and standard plastic molds. MIM thermal conductivity of the feed is several times higher than that of plastic, so the fluidity is worse. The shrinkage rate of MIM moulds is usually 15%~22%, which is much larger than that of plastic moulds, so it is more difficult to control embryogenic density and sintering size. Many companies make mistakes on this issue. In addition, metal powder is more destructive to the die than plastic. Above all, we need to make some changes in the design of MIM moulds:

A, Tool steel. High wear resistant heat treated steel should be selected.

B, Hot runne.The liquid hot runner is more stable than the electrothermal runner, and more uniform embryogenesis can be obtained, so the sintering deformation will be smaller.

C. Runner and rubber port. Because of the high shrinkage rate and the high thermal conductivity of the feed, the layout of the runner and the rubber port must be balanced, otherwise the shaping work after sintering will be more troublesome. Sometimes, it is even necessary to modify the dimension by CNC machining, which will increase the manufacturing costs.

D. The length of the feed head in the mould nozzle should be as short as possible, and the flow path of the feed should be shortened to reduce the heat loss.

E, Surface treatment of the die cavity. Blackprint is a common problem in MIM products. The treatment of die surface will improve it. In general, VDI18 discharge treatment is used in die processing.

Why Choose No.2 Machinery As Your China Manufacture Parter?

We focus high attention on talents scientific researching. In terms of elites and technology, we widely recruit undergraduate bachelors and graduate masters who study in MIM and machinery major. In order to found technology base, we also cooperate tightly with China famous universities like Central South University, University of Science and Technology Beijing, Nanjing University of Science and Technology and Shandong University of Science and Technology etc..

In the aspect of hardware, we have our own material feeding proprietary intellectual property right, professional design and tools making abilities. Regarding to equipments, we imported SHIMADZU integrated vacuum sintering furnaces from Japan, using German BASF catalytic debinding production techonology. Moreover, we have CNC lathes, heat treatment furnaces, magnetic grinding machines, carbon sulfur analyzers, flaw detectors, density analyzers etc., to ensure every machinery performance requirements.

Based on our strong researching and production ability, we are confident to be your reliable and priority choice supplier in MIM. Welcome to visit our factory!