Material: D2 tooling steel

Chinese mode: Cr12Mo1v1

USA mode: D2

Sweden mode: XW-41

Japanese mode: SKD11

Feature:Steel for mould cavity/mould core

The steel used in the die cavity/core should be able to withstand the wear caused by the die forming material. All steels in contact(including gates and runners) with die-formed composites should be made of tool steels with high wear resistance, high chromium content and hardness, such as D-2 or A-2 tool steels. H-13 steel can also be used because of its high hardness and coating. Any detailed parts that are not in contact with the die-formed composites can be manufactured with more standard S-7 tool steels.

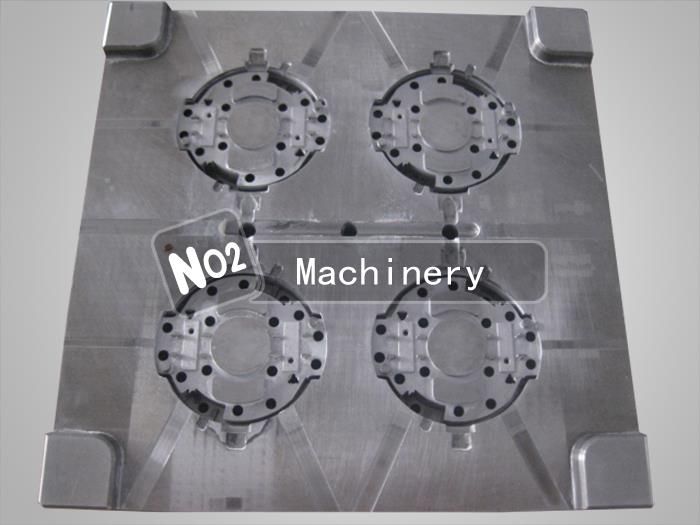

MIM technology can make various kinds of metal parts. If your part is made of stainless steel, steel, iron and the shape is complex, MIM is the best choice. If you want to make metal components by MIM, you need to send us the parts drawings, including PDF and 3D files in which, we can see the shape, sizes, tolerance and other requirements such as surface treatment, hardness(HRC). Also, we need to know the quantity for the part. Because to make MIM items, the mold is important. To make a mold is around 3000--5500USD that based on the shape, so if the customer have several parts to produce, we suggest to put them in one mold to save cost.